1961

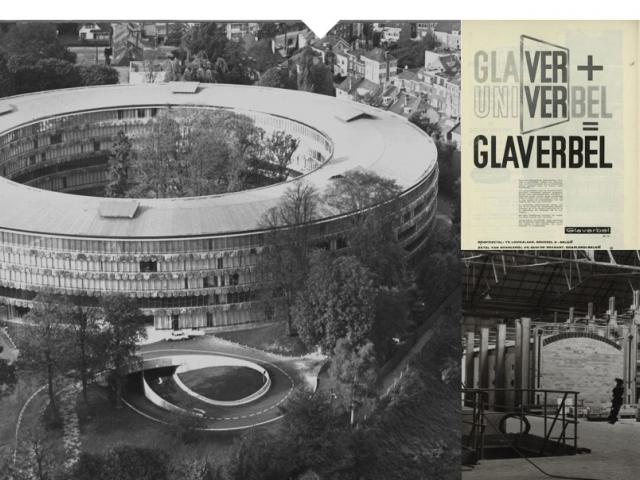

Birth of Glaverbel

With the rapid development of mechanisation, there was a concentration of the glass industry in Belgium. This led in 1961 to the merger of the two largest Belgian producers of flat glass, Glaver and Univerbel, to form Glaverbel. In 1965 Glaverbel set up the first float glass plant in continental Europe, at Moustier (Belgium).

1972

Diversification into glass processing

Between 1972 and 1981 the French group BSN (Danone) held control over Glaverbel and incorporated the latter into its flat glass division. The float glass revolution led to radical restructuring of the glass industry, with existing glass furnaces being shut down. The accompanying disruption to employment in the glass industry was exacerbated by the worldwide recession that hit the economy in the mid-1970s. In response Glaverbel introduced a policy of processing the raw glass into finished or semi-finished products.

1981

Geographical expansion in western Europe

In 1981 BSN spun off its flat glass activities, and Glaverbel was acquired by AGC. The launch of Glaverbel on the Brussels Stock Exchange in 1987 gave the company the financial resources it needed for an ambitious programme of growth, with geographical expansion in western Europe and investments in high-tech products.

1991

Pioneer and leader in central and eastern Europe

In 1991 Glaverbel was the first western industrial company to invest in the former Czechoslovakia, taking over the national flat glass producer (now AGC Flat Glass Czech) in stages. Buoyed by this success, in 1997 Glaverbel became the first western glass producer to invest in Russia, with a phased takeover of that country's largest glass producer (now AGC Bor Glassworks).

1998

Consolidation in western Europe and Russia

In 1998 Glaverbel acquired the European flat glass activities of PPG Glass Industries, with plants mainly located in France and Italy. In 2004 it reaffirmed its leadership in Russia with the construction of an integrated industrial complex in Klin, with combined production of float glass, mirror glass and superinsulating glass. This was the first glass plant in Russia ever to be built on a greenfield site by a western glass producer.

2002

Full integration into AGC

In 2002, as part of its worldwide reorganisation AGC took full control of Glaverbel, which was delisted from the stock exchange. In 2007, AGC adopted a single name for all its companies around the world, and so Glaverbel became AGC Flat Glass Europe, and in 2010, AGC Glass Europe.

2012

Expansion in the automotive and building sectors

In 2012 AGC Glass Europe teamed up with Interpane, a large German glass processor, thus expanding the group's capabilities in coated glass for the building industry. Then in 2015 it acquired NordGlass, a Polish company active in automotive replacement glass, making it the European leader in this sector. In 2016, AGC Glass Europe partnered with Induver, a glass manufacturer in Morocco, to set up a joint venture for manufacturing automotive glass destined both for Europe and for North African markets. This move marks the AGC Group’s first operations in Africa.

2021

Leading our industry to decarbonise

In February 2021, the AGC Group declared its goal of achieving net-zero carbon emissions by 2050. As transitional targets, the group has set a 30% reduction in GHG emissions and a 50% reduction in GHG emissions per unit of sales by 2030 (total of Scope 1 and 2; reductions from 2019 levels).

To contribute to the AGC Group objectives, AGC Glass Europe has set out a carbon reduction roadmap and monitors the progress of its carbon footprint on a yearly basis. AGC Glass Europe's roadmap is taking into account all parts of the value chain. This includes decarbonising the glass production processes by using highly efficient melting furnaces thanks to breakthrough technologies, low carbon electricity and increasing the use of cullet. It also means eliminating all CO2 emissions from the supply chain upstream of our processes and other indirect emissions by sustainably sourcing our raw materials as well as optimising the transport of our products.

Read more on "Contributing to a sustainable future"

Shaping the future of glass

The world around us is changing fast: smarter greener cities, advanced connectivity, and new models of mobility. By reinventing glass and continuously improving what it can do, AGC makes sure that glazing is a central part of enabling these technological revolutions. Some of these glass advances are already shaping our future way of living, moving and communicating.

Our mission is to constantly develop glass solutions for the buildings of tomorrow and drive the world to comfortable zero-carbon buildings. It is also to make sure our glass solutions fully meets the requirements for the vehicles of tomorrow by offering top of the range energy control, safety, aesthetics and connectivity features.

Read more on "Shaping the future with glass innovation"