1 tonne of cullet saves 1.2 tonnes of raw materials. Cullet allows to save a significant amount of melting energy. An increase with 10% more cullet means saving 2.5% of energy consumption. That means a strong decrease of CO2 emission is possible thanks to cullet recycling. Recycling of 1 tonne of cullet allows to avoid the emission of up to 0.7 tonne of CO2.

The average cullet ratio in our raw materials is close to 30% today and AGC Glass Europe aims to increase this ratio to 50% by 2030

Flat to Flat closed loop recycling

To achieve the objectives for flat glass in a climate-neutral Europe, a greater input of cullet is identified as one of the major routes to reduce CO2 emissions from manufacturing. It is therefore in our, and in the common interest of the flat glass industry, that an increased quantity of cullet returns to the flat glass industry in a closed-loop model, i.e. ‘flat glass to flat glass’. The sector sets the goal to promote close loop “flat glass to flat glass recycling” and no other forms of recycling (to other glass sectors) or downcycling.

The flat glass sector stands ready to use the available cullet, if uncontaminated, to further sustain its production, and reduce CO2 emissions from manufacturing. However, as the cullet used in our own production process must meet stringent specifications, we also actively seek out alternative routes for cullet that we cannot recycle in our own products. Today the clean cullet that can be used in float glass furnaces represents only a part of all the glazing waste collected because we need to ensure that the cullet is not contaminated, that means not mixed with other contaminant materials.

Three routes of recycling flat glass cullet

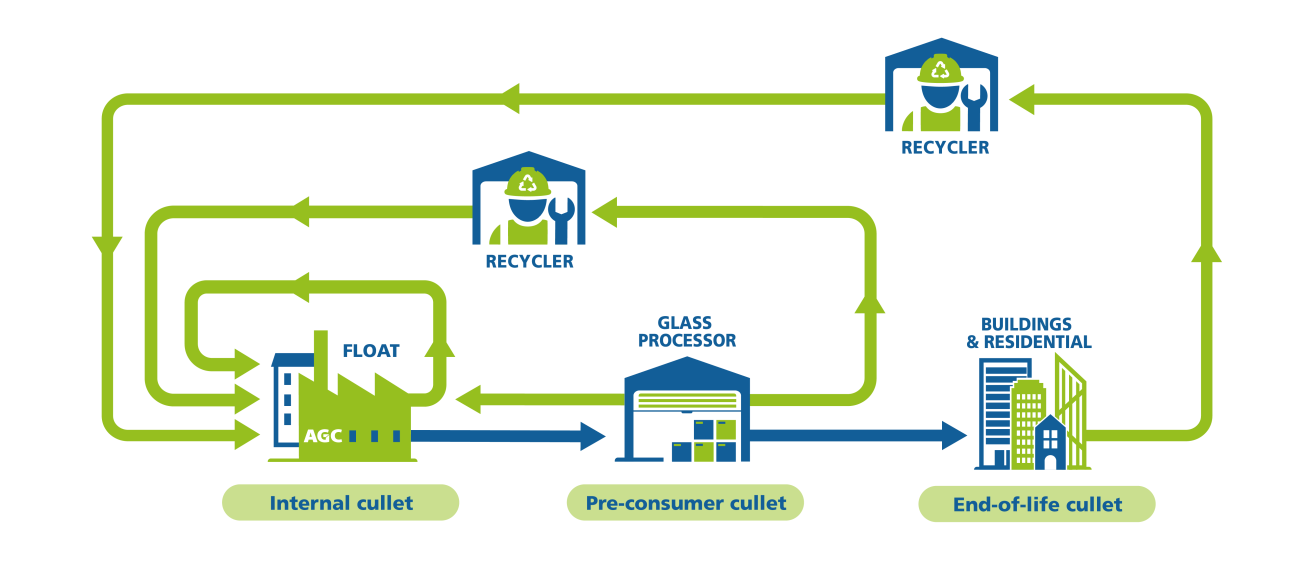

In cullet we distinguish 3 types of routes:

- Internal cullet : cullet at the glass production site,

-

Pre-consumer cullet : cullet at customers’ sites (glass processors)

It concerns cutting losses of flat glass panes occurring during the pre-processing and defective products. - End-of-Life cullet : cullet generated at the end of life of the glazing product

Cutting losses are uncontaminated and can return directly to the flat glass production. Product waste occuring after processing or at the end of life needs to be treated first by a flat glass recycler - that extracts the cullet from other materials - to send the cullet back to float production.

Out of the average 30% cullet ratio, the major part comes from internal cullet. To increase our cullet ratio to 50% by 2030, we need to find ways to increase the pre-consumer and end-of-life cullet.

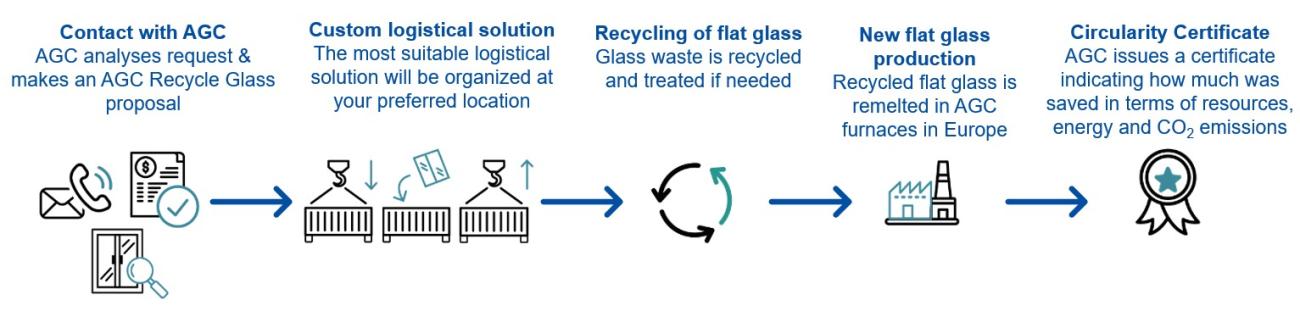

To address this issue and in the scope of the company’s Carbon Reduction Roadmap, AGC launches Recycle Glass, a program for delivering flat glass circularity .

AGC Recycle Glass

Recycle Glass is AGC Glass Europe's service of collecting flat glass waste from industrial losses and from deconstruction projects (end of life glazing from commercial projects or residential buildings) to be recycled and remelted in new, more sustainable, flat glass production. Recycle glass also aims to share the best practices in sorting flat glass waste and avoiding external pollution with the deconstruction and flat glass transformation actors in order to move to a circular loop of recycling (from flat glass to flat glass).

Watch the video "AGC Recycle Glass: delivering flat glass circularity".

AGC works with a partners network a.o. transporter, recycler, waste manager and deconstruction companies.

For end-of-life glazing, the process is :

- First, the window is removed from the facade and the frame is dismantled by the deconstruction company or the window installer. The glazing is collected in a dedicated container provided by AGC partners.

- The container is then transported to a selected flat glass recycler to process the glazing in order to extract the cullet, meeting the quality specifications for the production of flat glass.

- Finally, the cullet is transported to one of our closest flat glass production plants to be melted in the glass furnace. At the level of our float plants an even more attention than usual is applied to check and trace the quality of all those external cullet sources.

- A certificate is issued to the customer to assess of the savings on material resources and CO2

Circularity at the heart of the Oxy project

Immobel and its partner Whitewood have set very ambitious objectives when it comes to taking a sustainable approach towards the Oxy renovation project in Brussels. They conducted a full analysis of the building with a view to recycling or reusing as much as possible from the seventies-era building.

For the glazing they chose for AGC's Glass Recycle service. AGC worked with its recycling partner to collect and recycle the glazing removed from the façade by the customer’s deconstruction partner De Meuter. Finally, the cullet was transported to AGC Moustier’s plant to be reintroduced in the furnace and produce new flat glass with a reduced carbon footprint, Low-Carbon Glass.

The challenge of collecting End-of-Life flat glass

With the renovation wave of buildings at hand, a huge potential of cullet volumes sits in existing buildings. To increase the use of post-consumer cullet, more Extended Producer Responsibility (EPR) Schemes are to be set up to assure the dismantling, collection, and recycling, particularly for building glass.

In the Netherlands AGC helped to develop a national system of collection of flat glass from construction and demolition waste. Vlakglas Recycling Nederland (VRN) makes sure flat glass containers are available across the country to collect cullet. The system is financed through a tax on every m2 of insulated glass produced or imported in the Netherlands.

Cullet output is then sold by VRN. Initially main clients were glass container, glass wool and glass treatment companies. New agreements have been put in place to sell greater quantities to flat glass manufacturers.

In France, AGC partners with Valobat, a government-approved eco-organization for the EPR PMCB scheme in force since 2023. Together, we support the collection and recycling of end-of-life glazed joineries. AGC is also a signatory of the UFME charter, promoting best practices for high-quality waste management and sustainable recycling solutions.

Recycling other types of waste

Depending on the activities, various types of waste are produced by our plants. These include used refractories, sludge from wastewater treatment systems, waste oil from maintenance, ordinary trash from administration activities, etc. In line with the objective of avoiding landfill, for each production site we have implemented a progressive approach based on prevention, reuse, recycling, and incineration.

We have succeeded in recycling other types of waste in addition to glass cullet. For instance, most of the recycled sludge coming from wastewater treatment is now recycled in cement production.

More on our decarbonisation journey

Partnership AGC and SOLAR MATERIALS

AGC Glass Europe and SOLAR MATERIALS, a German cleantech startup specializing in the innovative recycling of photovoltaic (PV) panels, have entered into a strategic partnership that will focus on integrating high-purity recycled flat glass (cullet) recovered from end-of-life solar panels into AGC Glass Europe’s float glass production process.

End-of-Life Glazing Recovery at AGC Energypane

AGC Energypane launches its End-of-Life Glazing Recovery Pilot, a major step forward in advancing circularity in Belgium’s flat glass industry. This initiative aims to optimize the recovery of end-of-life glazing from AGC Energypane’s customers, thereby increasing the use of recycled glass in AGC’s flat glass production.