Usually in a float glass furnace, the glass is melted thanks to the heat produced by the combustion of fossil fuels. Natural gas burners radiate above the glass melt, allowing it to reach the 1.600°C melting temperature. Electro-boosting is based on the fact molten glass is an electrical conductor. Thanks to the injection of electrodes in the glass bath, the current passes from one electrode to another. By doing so, the current generates heat inside the glass in a way that is twice as efficient as with fossil fuels. The overall energy efficiency is then doubled. Since the electricity used has a low emission factor (**), the CO2 emissions’ drop is significant. Best case scenario, the emitted CO2 per molten ton is 6 times lower, when we switch from natural gas to a low carbon electricity.

(**) The emission factor is the amount of CO2 that 1 MWh of energy will emit during its production or its usage, whatever its type (fossil fuel or electricity).

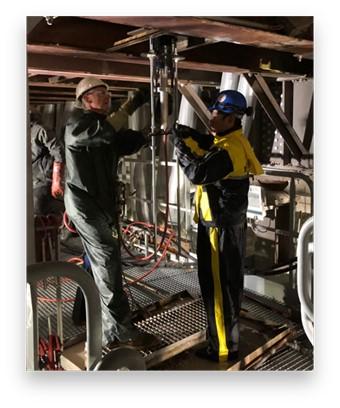

In 2022, the first furnace was equipped with the electro-boosting technology in Moustier, during the cold repair of the furnace. The technology was also installed on the float line in Seingbouse*** (France). This time when the hot furnace was in operation, which is a very challenging intervention. In 2023, the installation of electro-boosting was done on our site in Osterweddingen (Germany). The three plants are now fully equipped.

In the upcoming years, all our other float lines in Europe will be retrofitted with electrical melting.

(***) The installation in Seingbouse was partly funded with a grant as part of the French economic stimulus program “France Relance”, financed by the European Union – NextGenerationEU . The program “France Relance”, operated by ADEME, helps to enable the decarbonization of the French industry.