About the R&D project

The objective of the project is to design and build a novel hybrid glass furnace combining electric melting and oxy-gas combustion. The integrated design provides an alternative to the mostly natural gas fired flat glass industry. The highly electrified furnace provides a more cost-efficient and scalable solution to abate the CO2 emissions of the flat glass industry compared to other clean alternatives, such as a full clean hydrogen combustion option. The new design will be piloted through a partnership with Saint-Gobain in AGC’s existing patterned glass furnace in Barevka (Czech Republic). The hybrid furnace is expected to reduce the pilot site’s scope 1 and 3 emissions by 75% compared to the reference scenario.

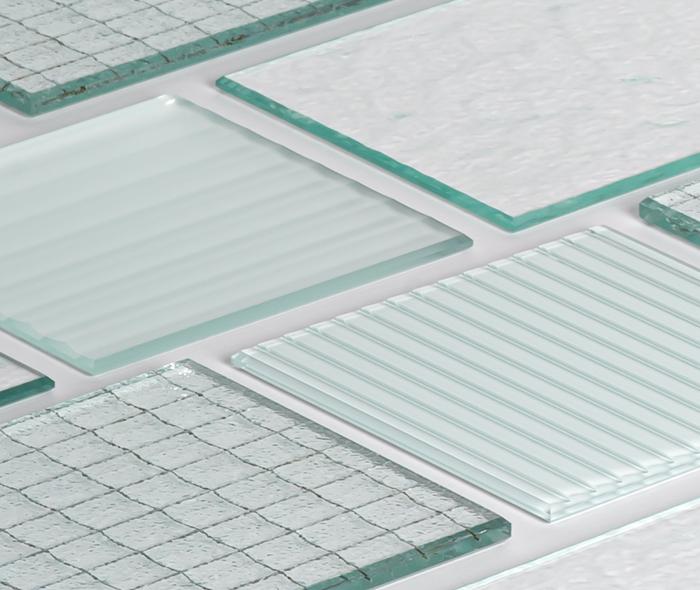

About the technology

This first-of-a-kind technology consists in an all-electric melting technology and oxy-gas combustion that are combined in an integrated furnace. This enables a 50% electrification rate whilst ensuring the high-quality standards that are necessary to float glass. Furthermore, the sustainability model of the project will be strengthened by substituting virgin raw materials with up to 100% recycled glass.

The flat glass sector accounts for ~4.6 million tonnes of CO2 equivalent of direct emissions annually in Europe (~75% from natural gas combustion and ~25% from raw materials). The novel furnace is therefore expected to reduce the energy-related emissions, resulting in a planned emission reduction of over 193 000 tonnes CO2 equivalent over the first ten years of operation.

Contributing to the REPowerEU plan

The project will contribute to the European goals set out in the REPowerEU communication, by reducing fossil fuel consumption in industry and transport, through innovative technologies and electrification.

The project is also expected to have a positive socio-economic impact at regional level. While the Barevka site currently produces ~90 tonnes of glass a day, the project has great potential for scalability through technology uptake at bigger production sites (600-800 tonnes daily).

Furthermore, there is significant replication potential throughout Europe, as the industry currently produces ~9 million tonnes of glass annually, and is a critical supplier to the construction, automotive, and consumer goods industries. Therefore, the technology could promote the upstream decarbonisation efforts of critical sectors (construction and automotive) while safeguarding the competitiveness of the EU flat glass industry.

More on the Volta project

Official start of Volta project : Cold repair of AGC plant in Barevka

The existing AGC furnace for the manufacturing of patterned glass in Barevka, Czech Republic has been stopped for the announced cold repair. The line will be refurbished with a complete new melting design, expected to reduce very significantly its direct CO2 emissions.