Coatings on glass

Energy consumption has been a source of growing concern over the past few decades, and limiting heat losses through glazing is a priority for glassmakers. AGC Glass Europe and its R&D Centre have long worked to improve the insulating properties of glass by applying coatings on it.

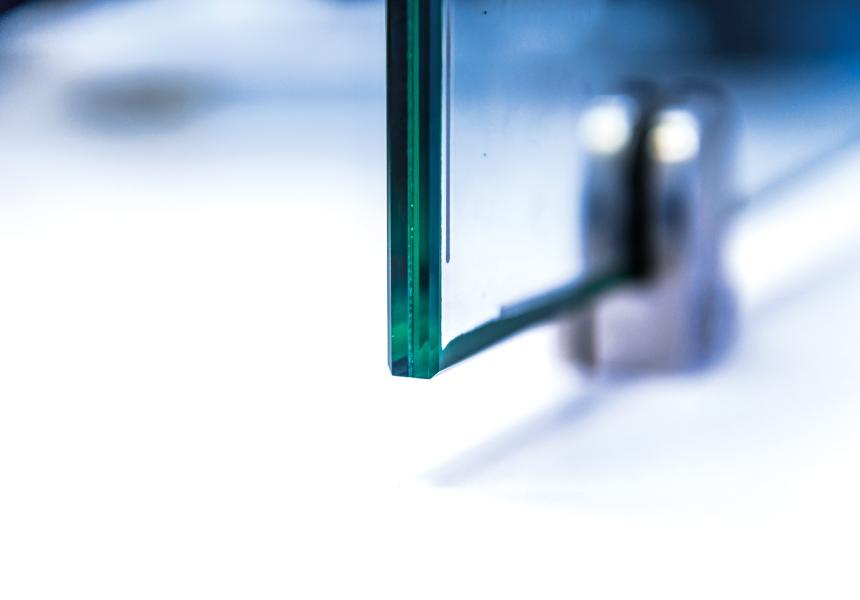

Coatings are extremely thin, almost invisible layers of metal oxide that are deposited on the glass to give it better insulation against cold and/or protection against the sun's rays. The coatings are applied either on-line on hot glass (pyrolytic coating) or by an electromagnetic process (vacuum coating).

There are two main families of coatings : the low emissivity and the solar control coatings.

A low-emissivity coating lets the sun’s rays pass through the glass yet reflects any indoor heat back into the room so that it does not escape – forming a shield against the cold. Generally used in double or triple glazing, this type of glass saves energy thanks to excellent thermal insulation performance. Its superb light transmission maximises the amount of natural daylight in any building.

A solar control coating is ideal for glass solutions that need to deliver the right combination of solar protection and thermal insulation. By filtering the sun, solar control coatings prevent excess heat inside the building while letting in plenty of daylight. This type of coating is superb for energy saving as it reduces air conditioning costs by preventing overheating.

AGC Glass Europe boasts a wide range of super-insulating coated glass, unified under the iplus and Planibel (Pyrolitic Low-e) brand names as well as an extensive solar control range with the brands Energy, ipasol, Stopray, Stopsol and Sunergy.

More on low-emissitivity coatings and solar control coatings on agc-yourglass.com

Energy : The power of solar control and thermal insulation

With AGC's Energy coated glass, you will experience abundant daylight while enjoying excellent solar protection. The Energy coating blocks out excess incoming heat while maintaining a high level of thermal insulation and letting plenty of daylight in. It is especially suitable for residential premises, delivering excellent comfort inside the building.

Its benefits :

- The Energy-saving coatings lead to lower air conditioning and heating costs.

- Maximum natural light entering the building.

- By regulating heat and cold, this glass provides optimal indoor comfort.

More on Energy solar control glass on agc-yourglass.com

Double and triple glazing

Insulating glazing units consist of an assembly featuring two or three sheets of glass separated by a space filled with dry air or gas. They are assembled into a surrounding metal frame which acts as a spacer. This design keeps heat in your home, allowing you to turn the heating down and save money. On warmer days, these glazing units will help to keep solar heat out, providing maximum comfort and wellbeing in all seasons. The latest generation of double glazing uses vacuum technology.

Comparison of single glazing versus double glazing and triple glazing

Single glazing has a U value of 5.8 W/(m².K). In such a case more heat is lost through the window compared with solar gain: the overall balance is a clear loss of energy.

The use of ordinary double glazing with a U value of 2.8 W/(m²K) improves the balance by reducing the amount of heating needed but it still remains negative with an overall energy loss.

The integration of low emissivity coating inside the double glazing cavity has then drastically improved the insulating power of the glazing while the light transmission, the thickness and weight of the product has been kept constant.

A further improvement has come from the triple glazing development, leading to the best insulation reachable but with an impact on the thickness and weight of the product as a decrease of the light transmission due to the bigger quantity of glass.

Finally the last development is the vacuum glazing, called FINEO. We combine the best performance of the triple glazing, with the weight and light transmission of a double glazing and a thickness close to a single glazing

By developing solid industrial and technical expertise in the manufacture of double and triple glazing, AGC has become a benchmark in insulating glazing. AGC Glass Europe offers a wide range of insulating glazing units marketed under the brand name Thermobel using low-e coatings or solar control coatings and Fineo, combining insulating coatings with vacuum technology. More on insulating glazing on agc-yourglass.com.

Thermobel : AGC’s insulating double or triple glazing

Thermobel is AGC’s brand of insulating glazing. Using AGC’s range of coatings, Thermobel delivers optimal year-round thermal comfort combined with a high level of thermal insulation and light and visual comfort. Following the needs, other functions can be integrated into Thermobel, such as solar control, acoustic comfort, safety and security, fire resistance, active functionalities and design. This makes Thermobel a truly multifunctional building product for use in homes, commercial buildings and industrial facilities.

Its benefits:

- High level of thermal insulation, light and visual comfort.

- Thermobel allows you to fine-tune and upgrade performance levels to suit your needs.

- Every Thermobel insulating glazing product is CE certified for use in residential, commercial and industrial structures.

More on Thermobel glazing on agc-yourglass.com

Fineo: The Future of Glazing

FINEO delivers the most advanced vacuum-insulating glazing technology, optimising indoor comfort & energy consumption by outperforming conventional insulating glazing. It is a unique innovation: a vacuum cavity between two sheets of glass, enabling the maximum insulation of triple glazing for the thickness of single glazing.

With a thickness of only 10mm, FINEO offers a Ug-value of 0.7, a sound insulation of 36(-2;-3), a better light transmission (+15%).The vacuum insulating glass is available in solar control version, combined with safety glass, acoustic glass and pyrobel fire-resistant glass, and other types of glass to provide the perfect multi-functional solution for a given project.

It can be used in new construction (residential, non-residential) and in renovation projects. For new construction, the increasing demand for energy efficiency in buildings requires intelligent and innovative solutions in terms of sustainability, technology and design, on which FINEO paves the way. In renovation, FINEO enable existing windows to be retrofitted with the most efficient and greenest glass technologies available. Combined with restoration glass it is an ideal solution for preserving the authenticity of historic facades.

FINEO is manufactured in Belgium, lead-free and 100% recyclable. It is first and only vacuum glazing in the world to be CE marked. This internationally recognized quality proof ensures construction customers of the high degree of quality, reliability and safety of our product. More on www.fineoglass.eu