Life Cycle Analysis

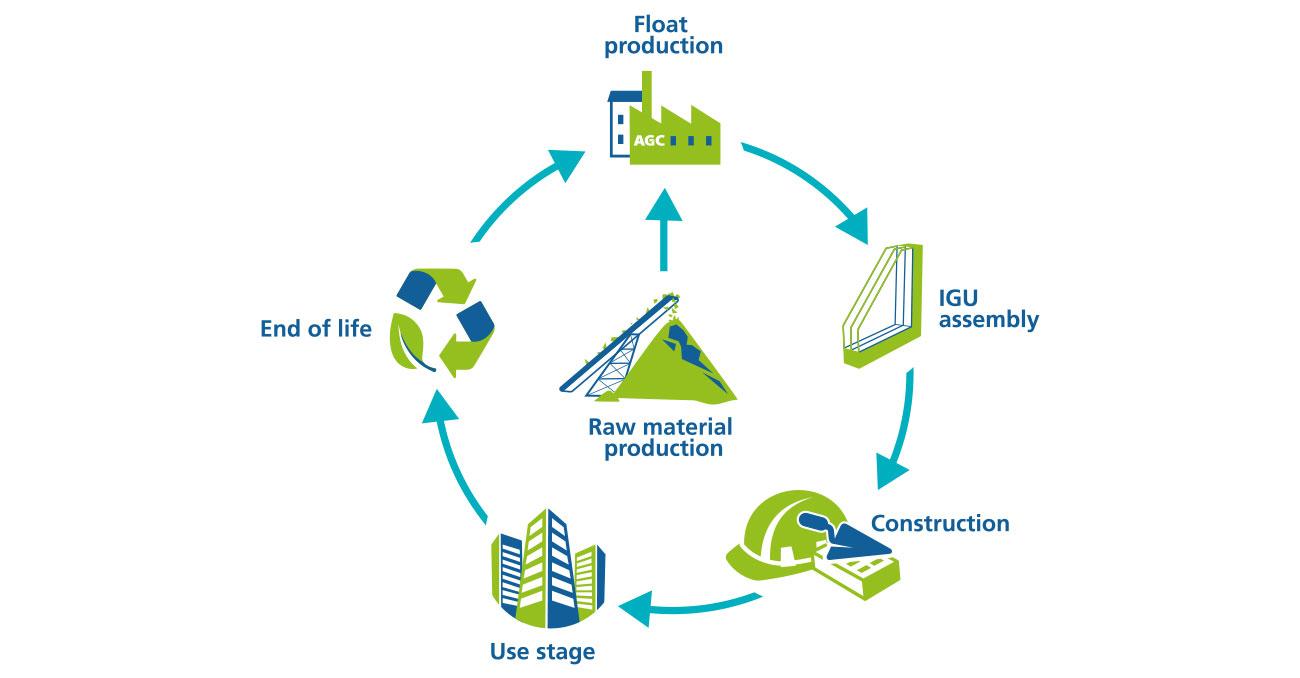

Life Cycle Analysis (LCA) is an internationally accepted (standards ISO 14040 & ISO 14044) and scientific tool that is used to quantify the environmental performance attributable to the different life stages of our product, including upstream stages such as raw material production and energy supply.

LCA is a standardized methodology whose goal is to assess the potential environmental impacts of a product, based on all the inputs and outputs involved during the manufacturing of a product as well as upstream and downstream processes: supply chain, packaging, transport, use and end-of-life.

Conducting LCA for our products allows us to update our EPDs and bring them into line with the latest European standards.

Environmental Product Declaration

An EPD is a way of providing science-based, verified and comparable environmental information. An EPD is thus a comprehensive and concise disclosure of a product’s environmental impact based on the results of a full LCA. EPDs follow international standards, including ISO 14044 and ISO 14025. Furthermore, the EN 15804 provides the core rules for the creation of Environmental Product Declarations for building products and materials, complemented for glass products by the product category rule EN 17074:2019.

AGC Glass Europe fully recognises the need for such a harmonised approach that is accepted by the industry, the public sector and non-government organisations around the world. The use of EPDs as best practice has been recognized and is internationally supported by the industry and the EU Commission, where the Construction Products Regulation (EU) No 305/2011 specifies that EPDs should be used when available. Companies and organisations in countries all over the world are working to improve the system.

Adding to this, the requirement for third-party verification confirms the robustness of the underlying calculations.

In a product Environmental Product Declaration (EPD), its climate impact, that is to say its Global Warming Potential (GWP) expressed in kg of carbon per functional unit, is the most scrutinized indicator. But an EPD is more than that and includes the overall potential environmental impact of the product with 26 other indicators such as the (GWP correlated) primary energy consumption or NOx and SOx-related air pollution (acidification and photo-oxidant formation ‘smog’).

Benefits of the Environmental Product Declarations:

- Life cycle approach

- Transparent disclosure of environmental information

- Independent verification.

EPDs also provide designers and architects with a way of identifying and assessing the potential environmental impacts connected with building/construction materials, products and building systems.

Indeed, within different sustainable building schemes such as LEED and BREEAM, credits can be earned by using products that have EPDs (or related information) in building design and construction. Considering that LEED and BREEAM apply to sustainable building projects, individual products can contribute to gather points :

- For BREEAM, 6 points are available in the category “Mat 01 Life Cycle Impacts” for considering a “low environmental impact over full building life cycle” and in which 1 credit is earned directly if the building products have an externally verified EPD.

- Regarding LEED, a specific point is available to encourage the use of products and materials for which life-cycle information is available. With our EPDs, projects can thus meet the LEED disclosure criteria “MR – Building Products Disclosure and Optimization – Environmental Product Declarations”.

The regulatory framework is also pushing the development of LCA at building level for coming projects. In that case, the whole building is assessed, taking into account the production and deconstruction stage, next to its use stage, that was already covered by the European Energy Performance of Buildings Directive.

Such assessment is based on construction materials EPDs. Several countries have introduced the need for such calculation for new projects respecting some criteria : France with RE2020, Denmark, Netherlands, Finland and Sweden, Germany, … For French RE2020 for instance, mandatory calculation of the 27 indicators of the EPD and maximal admissible limit for GWP decreasing over time.

AGC Glass Europe EPD journey

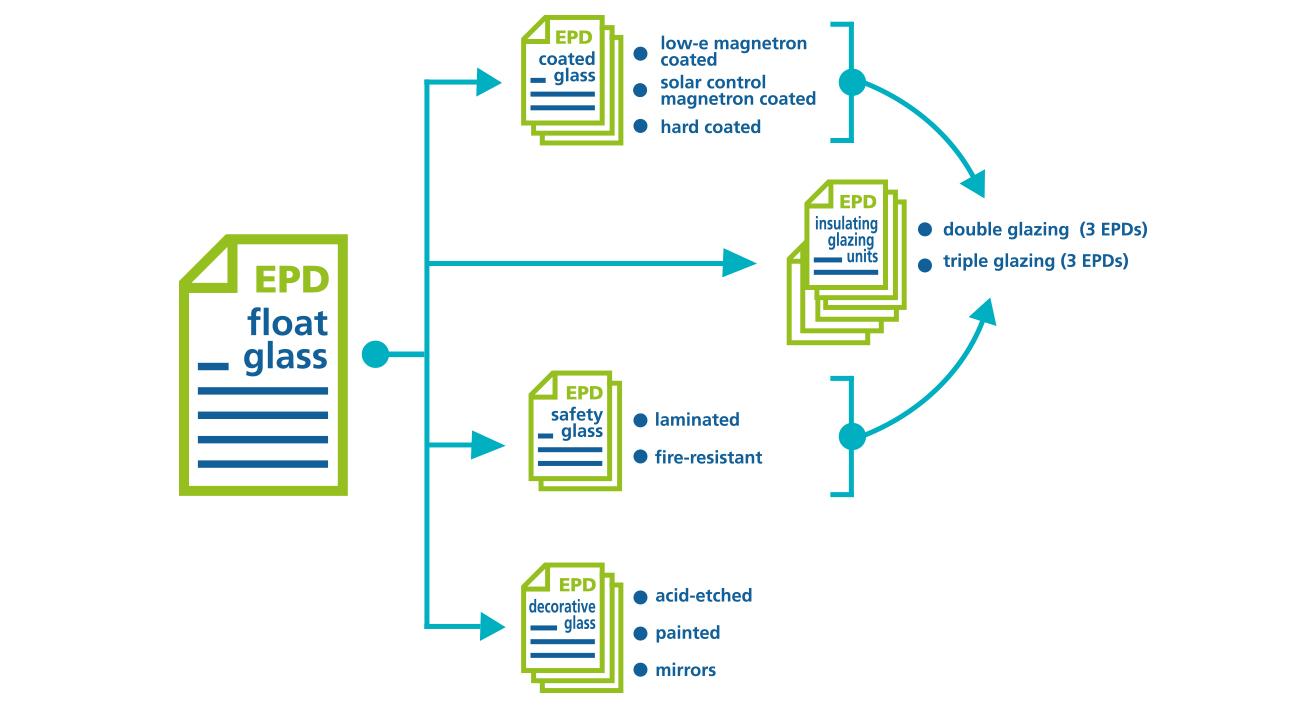

It started in 2009, with the publication of its first EPD covering its main primary product: float glass. Since then, the EPD programme has been constantly broadened. EPDs for processed products such as coated glass, laminated glass or decorative glass, were drafted based on the float glass EPD. Final products such as Insulating Glazing Units are also covered, based on the respective EPDs of its glass components.

All our EPDs benefit from third party verification that distinguishes the stewardship of our products in a way that customers recognise and accept. Most of our products are now covered by EPDs specific to AGC Glass Europe and third party verified. These EPDs are based on a dedicated data collection from all our plants, reflecting our exact processes and environmental performance.

Since the end of 2024, AGC proposes the exclusive service of providing the calculation of the product environmental properties for most of the architectural structures of its extensive products range in its Glass Configurator with the sending of the corresponding third-Party verified EPD. This upgraded tool will address the requirements for more precise and exhaustive documentation of the environmental performances of our products. Our customers require such documentation for regulation purposes or as asset in the competitive bid.

AGC has now included in its Glass Configurator similar possibilities of calculation and sending of third-Party verified EPDs for its Low-Carbon products range allowing few clicks comparison of the substantially lower environmental impacts of these products compared with the standard range.

Please contact sustainability@agc.com for more information.

Our EPDs can also be found in the French database for building products of the program operator, INIES