Hybrid melting, a technical breakthrough

Hybrid melting is a combination of the oxy-combustion technology and electrical melting technology.

Oxy-combustion consists in replacing the air used to burn natural gas, by pure oxygen. It provides different advantages, such as energy savings or NOx reduction. To further enhance the energy reduction, oxygen and natural gas are preheated at 500°C by the tank exhaust gases. AGC knows this innovative technology well as it is operated across the company. AGC Boussois plant, in the north of France, has been the pioneer installing that system.

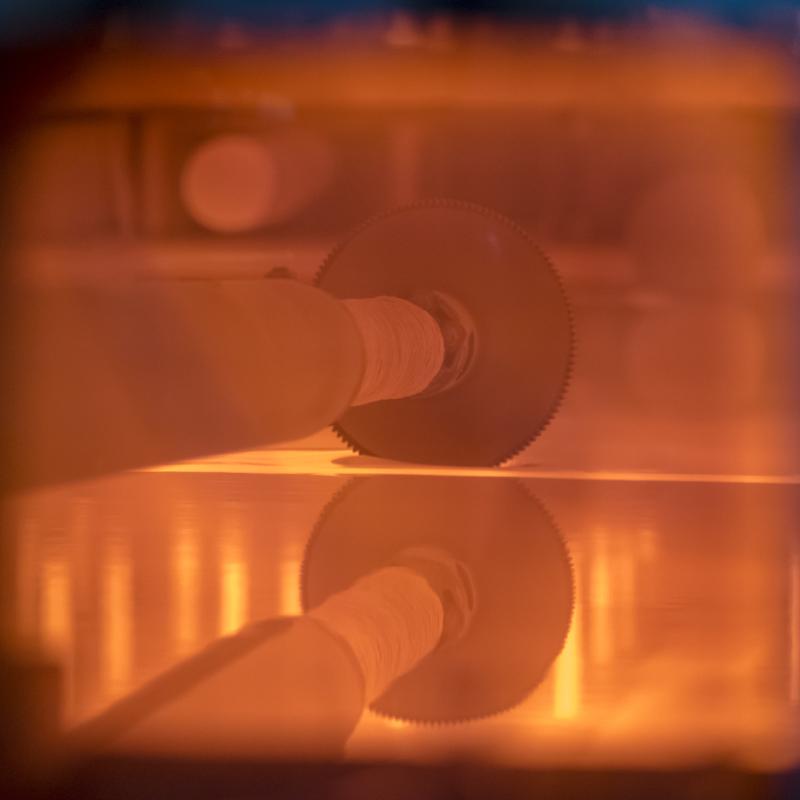

Electrical melting consists of introducing electrodes inside the glass melt, which are then fed by current, and heat the glass melt. On standard float tank design, electrical melting can be used at a low electrical/gas ratio and is known as electro-boosting. (more in "Electro-boosting")

It is a technical breakthrough compared to the current technology used in flat glass furnaces fired by natural gas.

This development will pave the way to the conversion of industrial flat glass lines in such a way that it can be powered mainly by low carbon electricity, which is more efficient than any gas solution, and has significantly reduced carbon emissions, for the customers’ benefit.

The new technology is expected to be implemented on AGC’s patterned glass production line in Barevka (Czech Republic) to be successfully operational by the 2nd half of 2024.