TIREXtreme glass

It’s a test of any company’s innovation culture when a client comes to them with a highly specific request in a technical field. AGC faced this very challenge when a pioneering Swedish infotainment company asked for a bespoke glass solution with high near-infrared (IR) transmission qualities to accompany its new multi-touchpoint screen recognition technology. Hard work, flexibility and a spirit of enthusiasm and cooperation culminated in a new class of ultra-clear touch-responsive glass, which can be produced cost-effectively on current production lines. Innovation shaping new potential for glass.

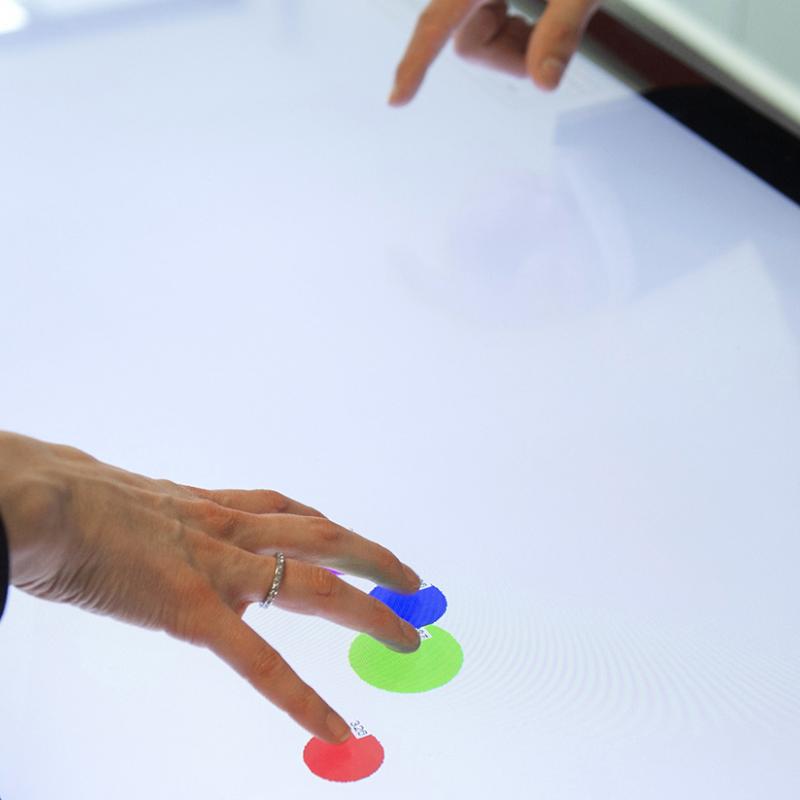

The outer glass used in touchscreens – in everything from mobile phones to navigation devices and info-points – is a coated glass that conveys electricity. This technology allows for no more than two fingers or ‘touchpoints’ to be used at the same time, and it’s very difficult and expensive to scale up to large screens (>20 inches) with multi-touch functionality.

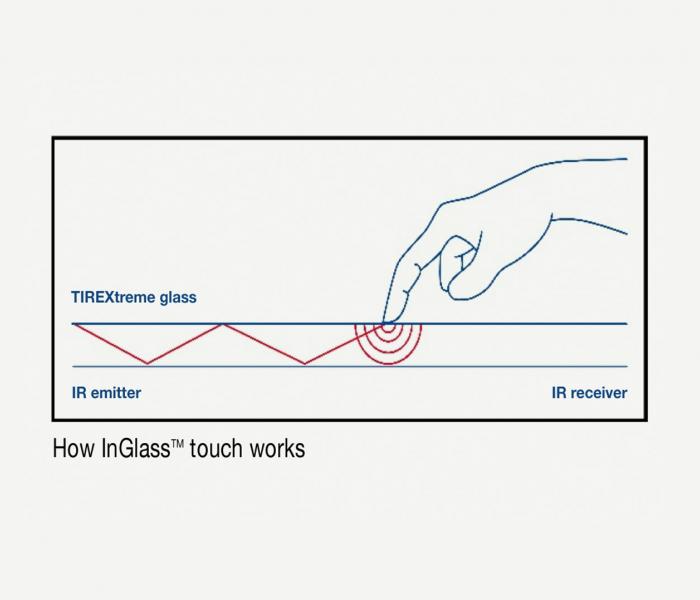

The technology developed by AGC’s Swedish client offers multiple touchpoint recognition without the need for a conductive coating on the glass. Their clever system uses invisible infrared light to detect different touchpoints. The infrared is projected transversally into the glass and when outside contact is made, the touchpoints trigger a response. This IR-based system is able to process up to 80 touches simultaneously and can be scaled up to even the largest touchscreen applications, up to 100 inches.

And AGC’s challenge was to develop an ultra-thin glass with exceptionally high-IR transmission qualities especially for this promising new technology.

The idea for TIREXtreme came from earlier research on the composition of ‘extra-clear’ glass for solar applications. But even this extra-clear glass absorbed too much of the near- infrared light. Further reductions of the iron content would start to impact on the glass transparency, so the researchers tested other solutions. After several changes in the glass composition, they came up with a product six times less light absorbent than AGC’s best glass for solar applications, with a resulting clear glass finish.

Developing a new glass product from research to industrial phase can take anywhere up to three years. But AGC’s innovation culture and lean organisation – a team with one person each from marketing, R&D and operations – shaved not months but years off this. The first feasibility test for mass production on an industrial float line took place in its Mol plant just four months after the first client contact. Mass production of the resulting TIREXtreme product line started six months later!

Product highlight

While offering the same aesthetic properties as clear glass, thanks to its special composition TIREXtreme has near-infrared absorption up to 30 times lower than traditional clear float glass and 5 times lower than extra-clear glass. TIREXtreme is available in various thicknesses, ranging from 0.5 to 5 mm, and dimensions up to 3.21 m x 6 m. It works well even when subjected to chemical or thermal changes – such as curving or toughening – during manufacturing. Apart from touchscreens, the glass can be used for light-control glass roofs and potentially for products that have a multi-touch function with or without a screen.

Learn more about TIREXtreme glass on YourGlass.com

Innovation highlight

Working hand in hand with the customer, AGC developed a new type of glass with high-near-infrared transmission qualities. First, the R&D team had to understand the new touchscreen technology, in particular the near-infrared transmission specifications, and the customer needed a crash-course in glass manufacturing. AGC researchers quickly realised they needed to develop a new tool to measure IR transmission through the length of the glass, and it had to be extremely accurate to show if the glass was suitable for multi-touch screens.