To achieve this drastic reduction in embedded CO2, all parts of the value chain needed to be taken into consideration. This included limiting direct carbon emissions from the glass production processes as well as lowering all CO2 emissions from electricity production, the supply chain upstream of our processes and other indirect emissions.

AGC successfully produced its first Low-Carbon Glass at the AGC plant in Moustier (Belgium) in 2022, Since then, it has expanded the production to the sites in Seingbouse (France) and Osterweddingen (Germany), continuing to apply its holistic approach that covers six key areas.

1. Sustainable sourcing of raw materials

Moustier – the first float glass production facility established in continental Europe – benefits among other things from the local availability of pure sand requiring minimal treatment before its use in float glass production. For several years now, 75% of the raw materials – not just sand, but also other raw materials – have been transported by barge to the plant located along the river the Sambre to be unloaded on-site.

Soda ash is a key raw material in glass production since it reduces the melting temperature of sand, the main ingredient. The carbon footprint of soda ash varies significantly depending on the process used to produce it. The Low-Carbon Glass production at Moustier plant is based on soda ash that has a reduced carbon footprint.

The other plants producing Low-Carbon float glass present a similar advantage with the availability of local sand requiring minimal processing. The transport to the plant has limited impact thanks to the shorter distances involved. This low impact can in some case be supplemented through the use of biodiesel. Soda ash with a reduced carbon footprint is also used at those plants.

2. Use of highly efficient melting furnaces

The first production campaigns were done on one of the furnaces in Moustier taking advantage of a recent cold repair (melting furnaces are completely overhauled every 15 to 18 years), incorporating new technologies, such as electro-boosting, that use electricity to melt the sand, to reduce dependence on imported natural gas. This innovative production process is a big step forward in the company’s overall roadmap to carbon neutrality.

In the meantime, AGC deployed Low-Carbon Glass production at float furnaces showing similar high efficiency due to recent upgrades including improvements in electro-boosting capacities.

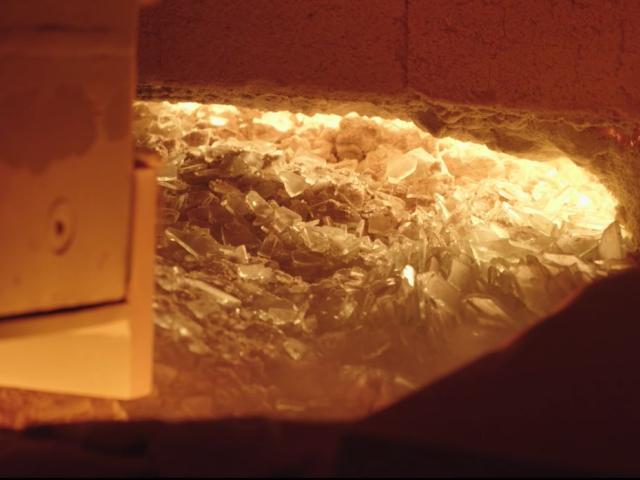

3. Increased use of cullet (recycled glass)

The three lines currently producing Low-Carbon float glass are capable of working with high levels of recycled glass by leveraging multiple recycling streams. For glass production with a reduced carbon footprint, new cullet streams will significantly boost the recycled content of the glass to more than 50%.

4. Use of green energy sources

AGC leverages solar panels to maximise on-site renewable electricity. This on-site produced renewable electricity, is supplemented with renewable electricity from the grid obtained under Power Purchase Agreement (PPA) or covered by a Garantee of Origin (GoO).

5. Optimisation of transport between Group sites for finishing processes

Logistics are also part of AGC's holistic strategy. In order to maximally enhance synergies between production and the finishing process and while also reducing transport and CO2 emissions, AGC laminates the glass sheets into safety glass at the Moustier plant itself, while coatings are applied at the coating plant in Lodelinsart, just 25 km away. The situation is even more favourable for the two other production sites at Seingbouse (FR) and Osterweddingen (GER) as they are both fully integrated and feature both lamination and magnetron coating capacities on-site.

6. Optimisation of transport for finished products

Transport distances for end products are optimal thanks to the strategic locations of these three plants in the heart of densely populated areas of northern France, the Benelux countries and western Germany – with millions of customers less than 250 km away.

About AGC's Low-Carbon Planibel Clearlite

AGC's Low-Carbon Planibel Clearlite is a low-carbon float glass whose Global Warming Potential has been reduced to 5.5 kg of CO2 eq. per m² (4 mm thick). It can be supplied – after further processing in compliance with the same holistic principles - in AGC’s key ranges of functional glazing products, including among others:

- safety glass: Low-Carbon Stratobel and Low-Carbon Stratophone

- thermal insulation glass: Low-Carbon iplus 1.0 and Low-Carbon iplus 1.1

- solar control glass: Low-Carbon Stopray and Low-Carbon Energy

These new Low-Carbon Glass products deliver the same aesthetics, quality and technical performance as traditional AGC float glass products.

Learn more at agc-yourglass.com

The first Low-Carbon Planibel Clearlite was successfully produced at the AGC plant in Moustier, Belgium. In 2024, the AGC plants in Seingbouse (France) and Osterweddingen (Germany) also started producing Low-Carbon float and now many AGC production lines are delivering Low-Carbon Glass products.

More on our decarbonisation journey

Now available : Low-Carbon Pyrobel Glass

With a view to meeting growing market demand and reducing the environmental impact of its production processes, AGC Glass Europe announces the launch of Low-Carbon Pyrobel Glass, its new fire-resistant glass product featuring significantly reduced embodied carbon.

Increasing the use of cullet

Glass is endlessly recyclable like no other product. Our main objective is to use as much glass cullet as possible in our production processes. The use of cullet avoids CO2 emissions, since cullet requires less energy to melt, and replaces carbonated raw materials. Cullet is a key material to save natural resources and energy.