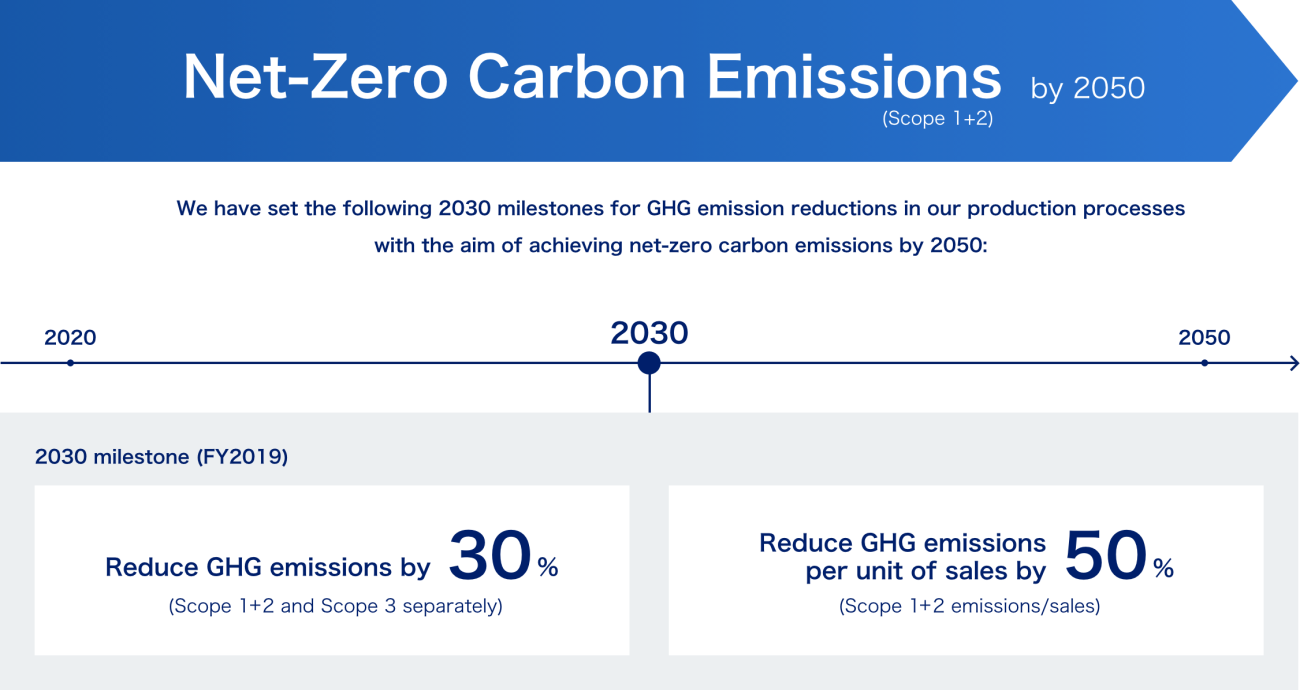

Aiming to achieve net-zero carbon emissions by 2050.

In February 2021, the AGC Group declared its goal of achieving net-zero carbon emissions by 2050. As transitional targets, the group has set a 30% reduction in GHG emissions and a 50% reduction in GHG emissions per unit of sales by 2030 (total of Scope 1 and 2; reductions from 2019 levels).

AGC Glass Europe is committed to reaching the AGC Group objectives and set out a roadmap to carbon neutrality. It monitors the progress of its carbon footprint on a yearly basis.

About the three scopes of GHG emissions

The scopes of carbon emissions were introduced by the Greenhouse Gas (GHG) Protocol, the internationally recognized standard for corporate carbon footprint calculations. They break down GHG emissions into 3 different categories, facilitating the work of assessing the carbon footprint.

- Scope 1 = direct emissions occurring at the production plants

- Scope 2 = indirect emissions from electricity production

- Scope 3 = indirect emissions from upstream and downstream activities along the value chain

Using resources effectively

In addition to the above target reductions of greenhouse gas emissions, we are working to make effective use of limited resources. Therefore, AGC Glass Europe is taking on the challenge to reduce its energy consumption, its water consumption and minimize waste output during the product’s manufacturing process. It will also reduce the amount of virgin raw materials (raw materials made from natural resources) used in products and increase the proportion of recycled raw materials.

Green product design

AGC Glass Europe is committed to drive the development of new products with better environmental performance during their entire life cycle, including the recycling at the end of life. Many products from the AGC Glass Europe’s portfolio have a positive impact during their use stage: they can reduce the energy consumption and therefore the CO2 emissions of users, or they can generate energy in a sustainable way. AGC Glass Europe also uses environmental-friendly materials during the production processes, for the products to be safe and healthy during the use stage, and to allow recycling at the end of life.

Our main emphasis for achieving the objectives

All plants, divisions, purchasing and other corporate services will successfully work on achieving the Group objectives by:

- Improving the energy efficiency of their manufacturing processes or activities

- Reducing the environmental impact of their manufacturing processes or activities

- Certifying the environmental management systems

- Enhancing “Green Purchasing” and environmental audits of suppliers

- Identifying, reducing and replacing the hazardous substances in the purchased materials that end up in products

- Ensuring compliance with the REACH and other regulations on chemical substances.

- Making greater use of multimodal transportation

- Increasing the environmental awareness at each level in the organisation.

The R&D and Engineering activities will focus on:

- Innovation in the manufacturing processes, in the aspects of energy, emissions and production efficiency

- Developing and renewing products that save energy and contribute to sustainable development, such as coatings and photovoltaic products or applications

- Research, trials and projects aimed at extending the possibilities for recycling of our products at the end of their life

- Replacing of the hazardous substances in our processes and products, beyond what is required by legislation.